The BIOSCHAMP legacy

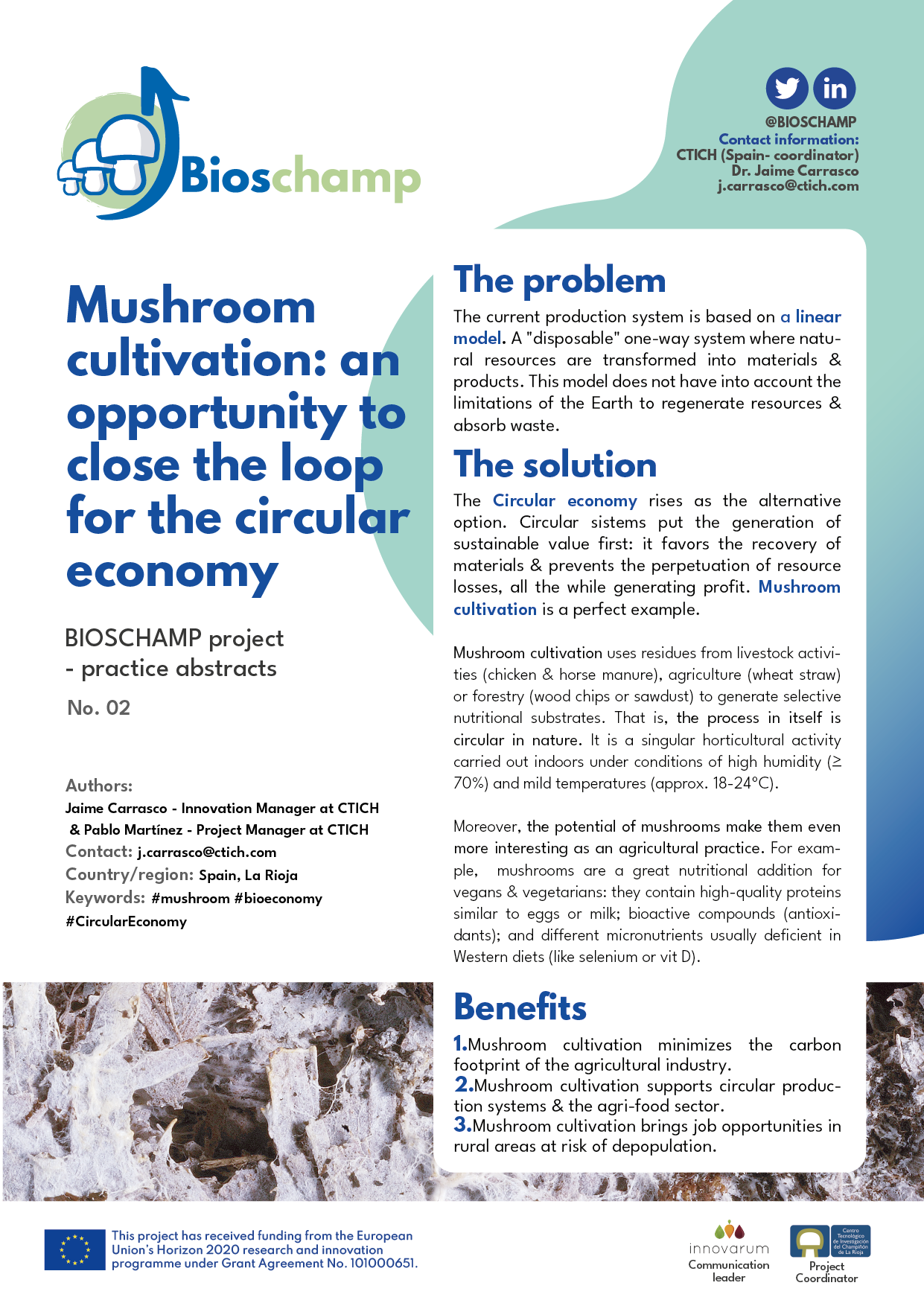

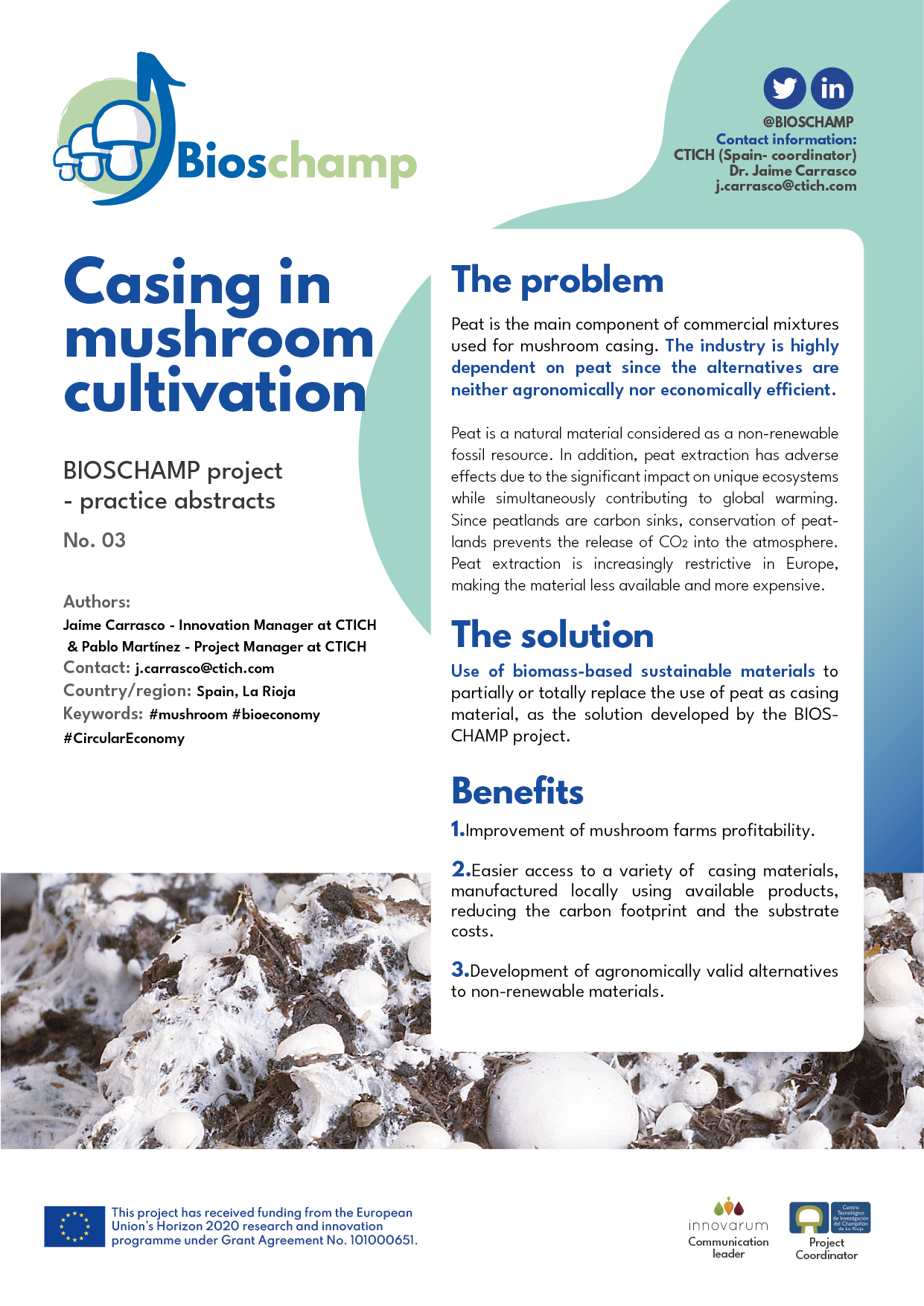

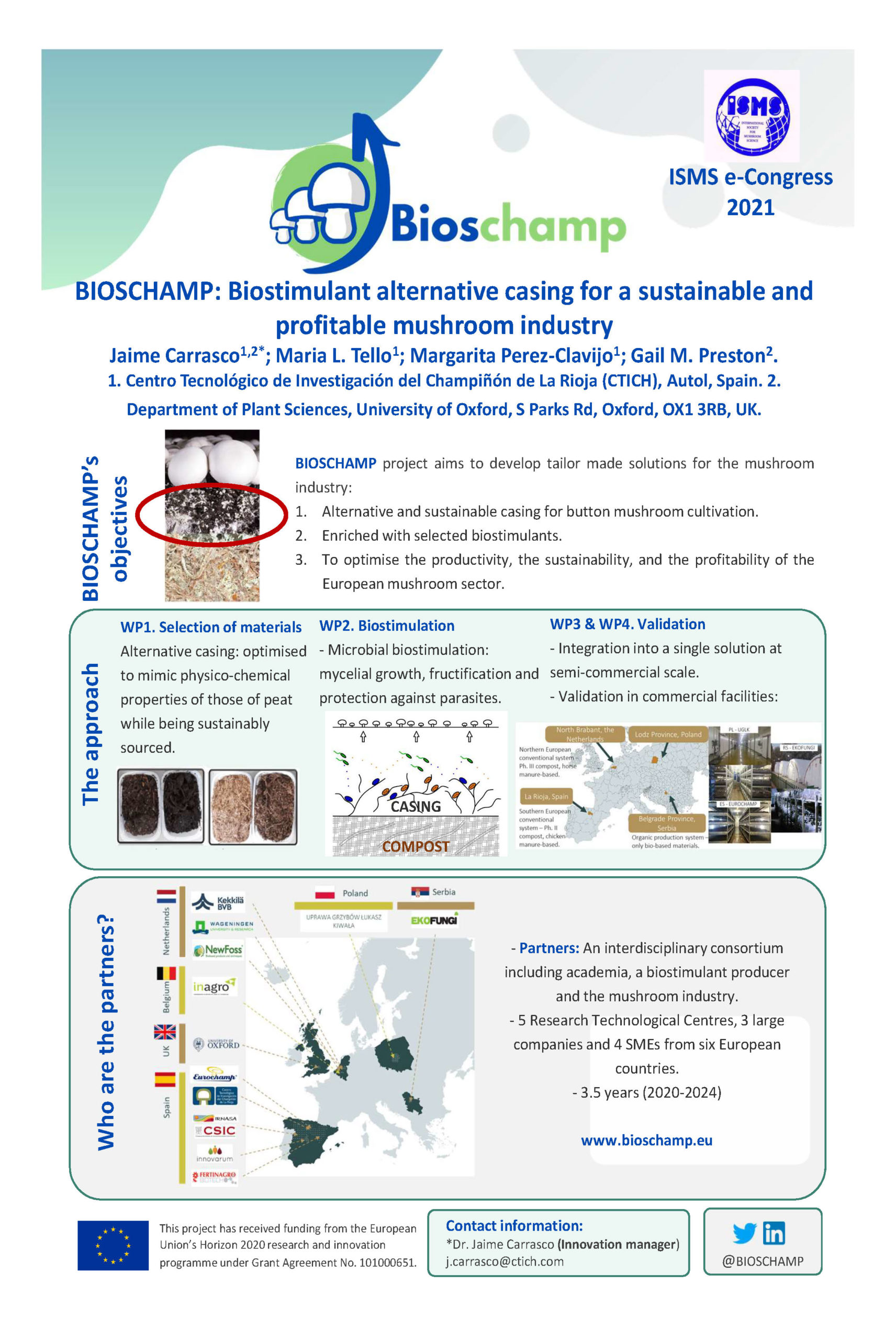

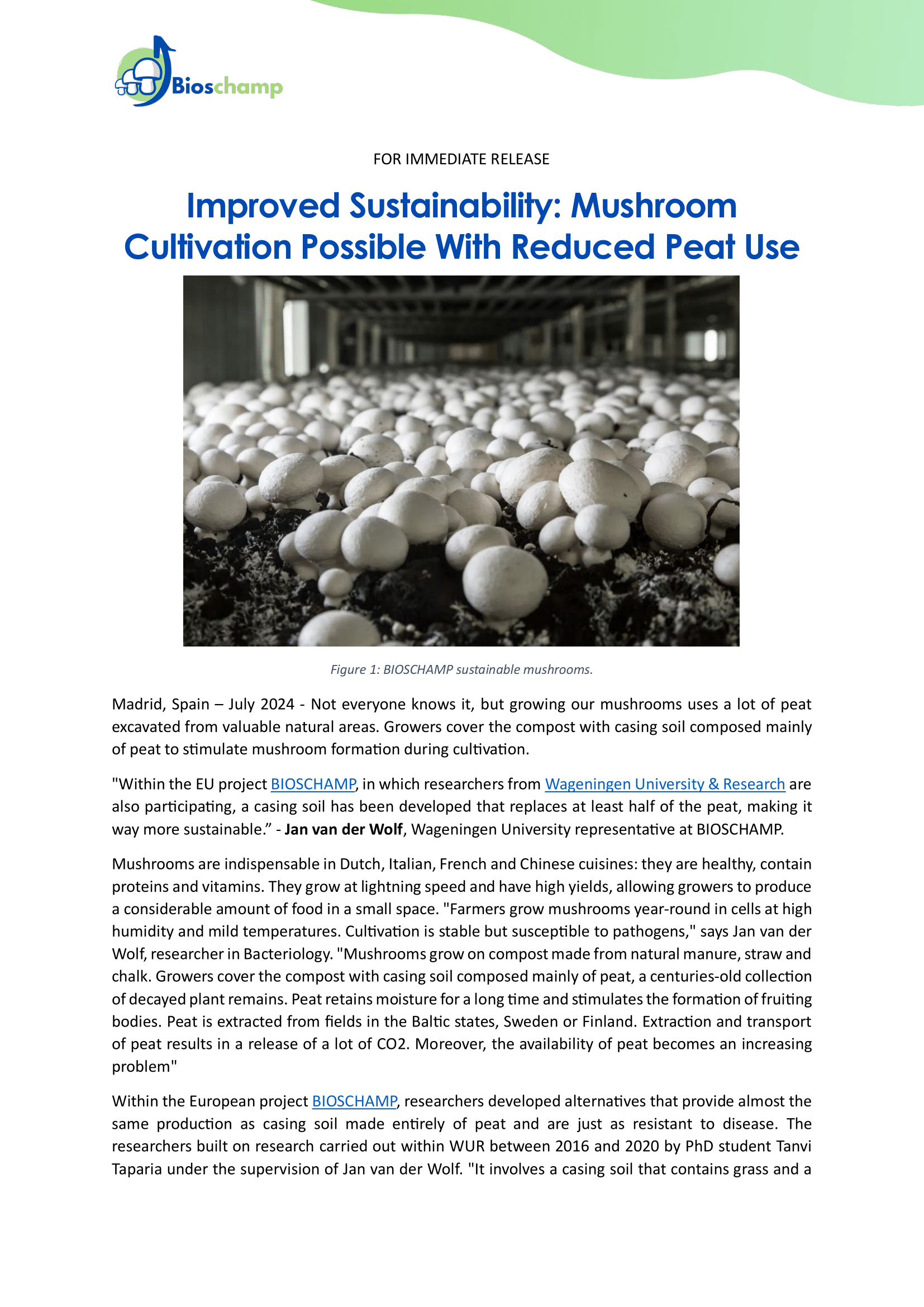

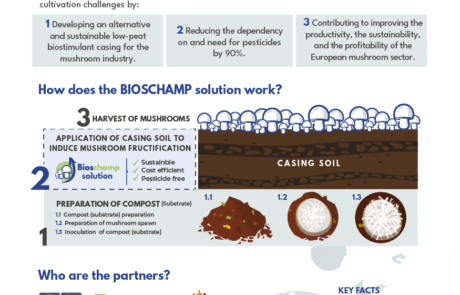

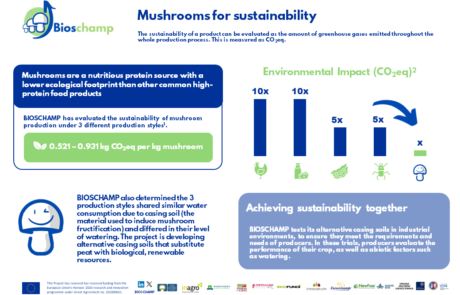

The goal of BIOSCHAMP was to develop an alternative and sustainable low-peat casing for the mushroom industry, reducing the need for pesticides and contributing to improving the productivity, sustainability, and the profitability of the European mushroom sector.

The final event, videos, media mentions…. A wrap-up to explore the BIOSCHAMP results and implementation.

Lessons Learnt & Main Takeaways

On alternative casing soils

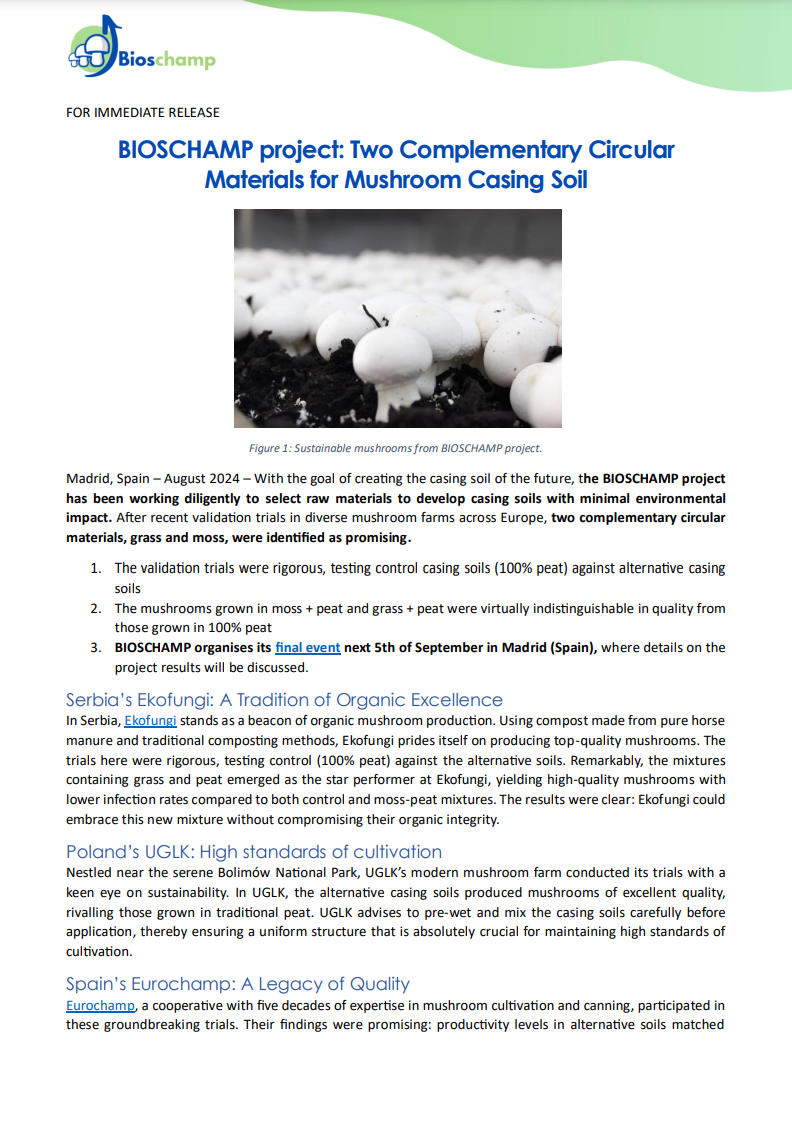

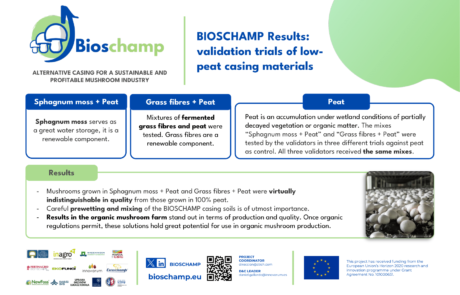

NewFoss urban grass fibers and sphagnum moss combined with peat in a 1:1 volume ratio achieved promising levels of productivity (kg mushroom/m2) compared to traditional casing, and mushroom quality was virtually identical.

Through these promising results, BIOSCHAMP showed it is feasible to substitute half of the peat used as mushroom casing for non-fossil resources while achieving comparable mushroom production.

These advancements represent a significant step towards a more sustainable mushroom industry. For these solutions to reach the market, further research is needed e.g., on how to tailor these alternative casing materials to achieve maximal productivity in each production style, and on the economic viability and impact on mushroom growers’ profits.

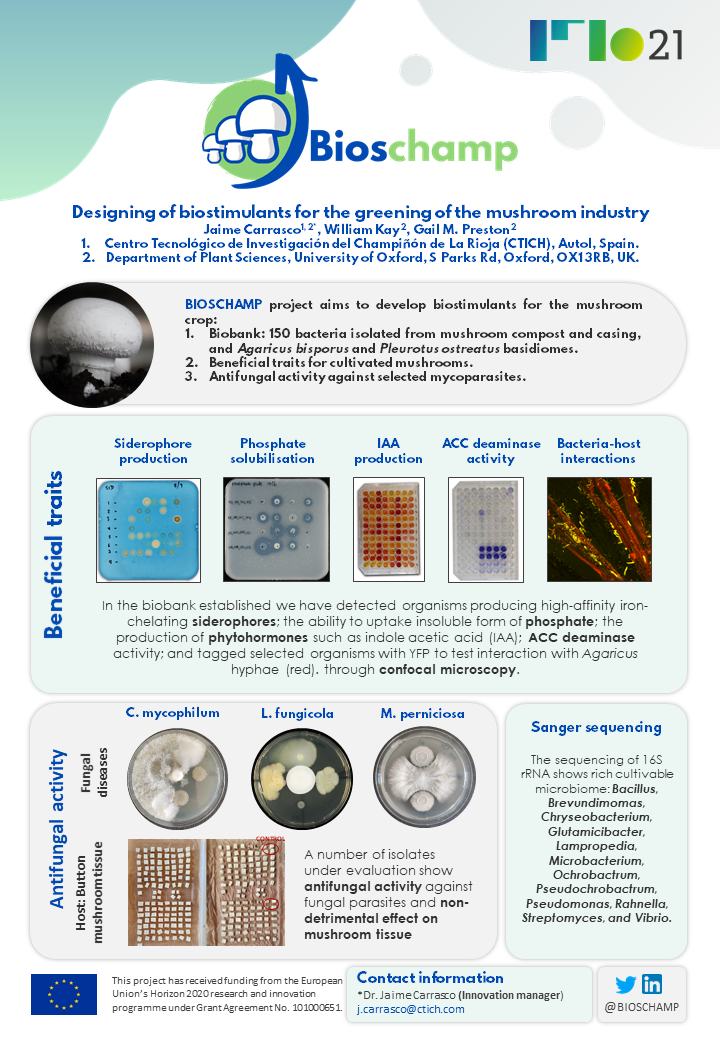

On biostimulants and their activity

The biostimulant activity of B. velezensis is likely to be caused by the production of fengycins and other antimicrobial compounds. This species inhibits mushroom parasites without negatively impacting mushrooms, thus postulating as a promising biostimulant for mushroom production.

However, we did not observe biostimulant activity when bacteria were produced at large scale (100 L). Further research is required to achieve industrial-scale production of this microorganism while retaining biostimulant activity.

Moreover, although B. velezensis could be isolated from mushroom casing, it did not maintain a high population density when introduced into mushroom growing conditions.

Research and policy gaps to be tackled

For the mushroom industry to adopt BIOSCHAMP solutions, efforts should be dedicated to expand current EU regulation and fill in existing knowledge gaps.

Key policies to be modified are EU Regulation 2018/848 (which currently prevents adoption of BIOSCHAMP results by organic mushroom producers) and EU Regulation 2019/1009 (which forbids commercial use of bacterial strains studied in BIOSCHAMP as biostimulants).

Further lines of research include economic assessment and design of the operational chain of both BIOSCHAMP alternative casing soils, scalability of biostimulant production, monitoring techniques for B. velezensis, production of fengycins, and transferability of active substances present in straw. Stakeholders should be informed about the latter.

Public Deliverables

Publications

Peer-Reviewed publications

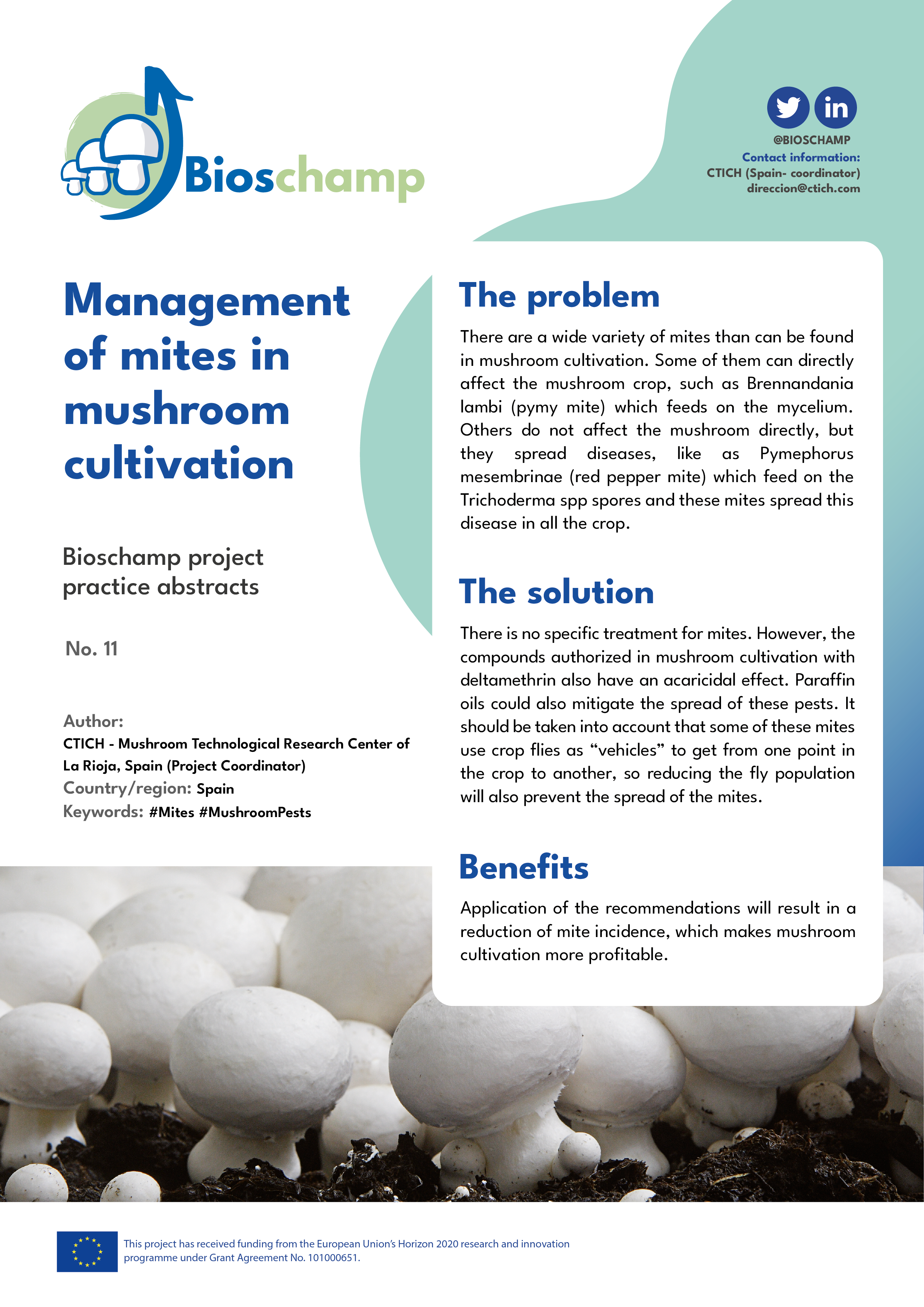

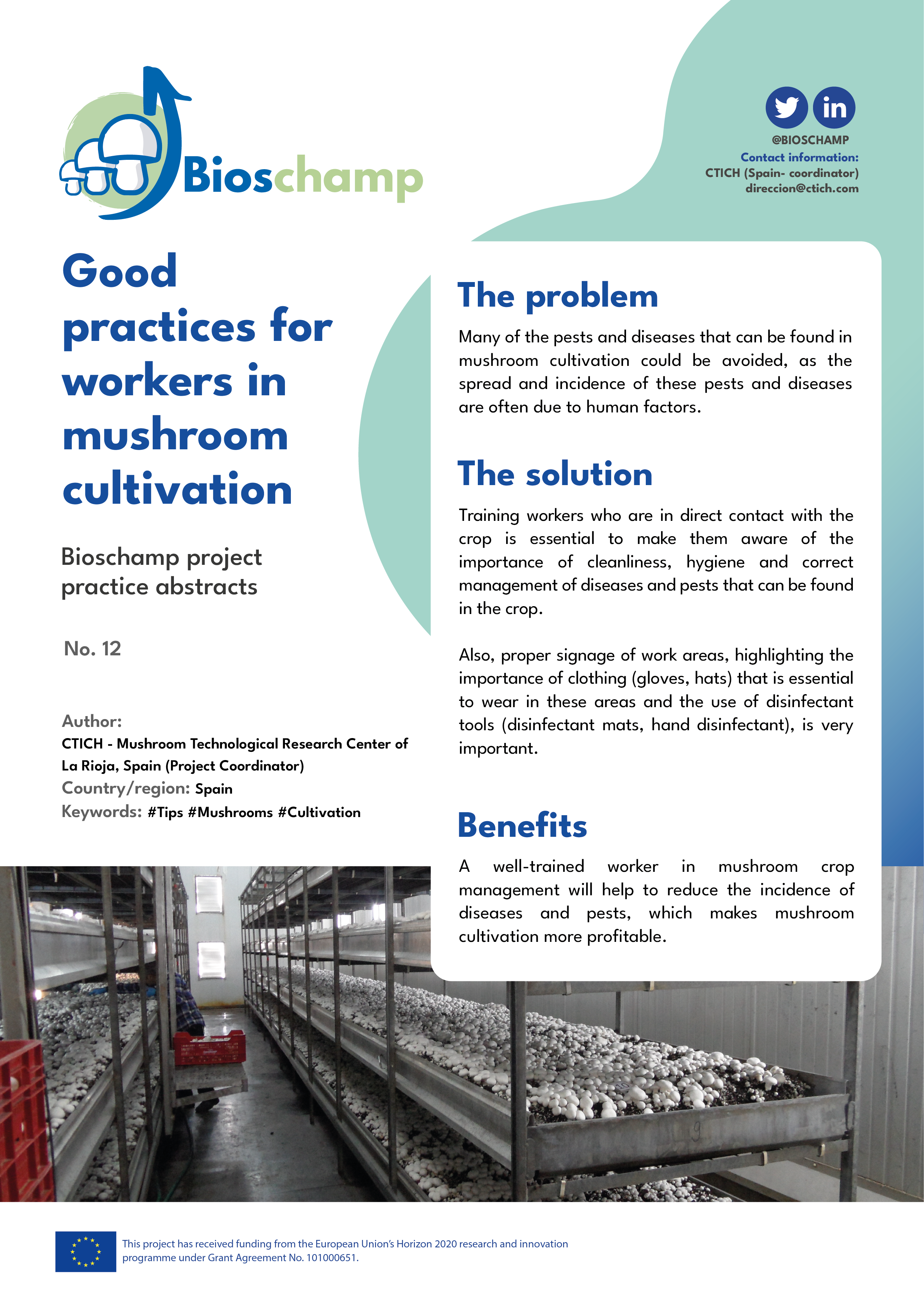

Practice Abstracts

Posters presented at conferences

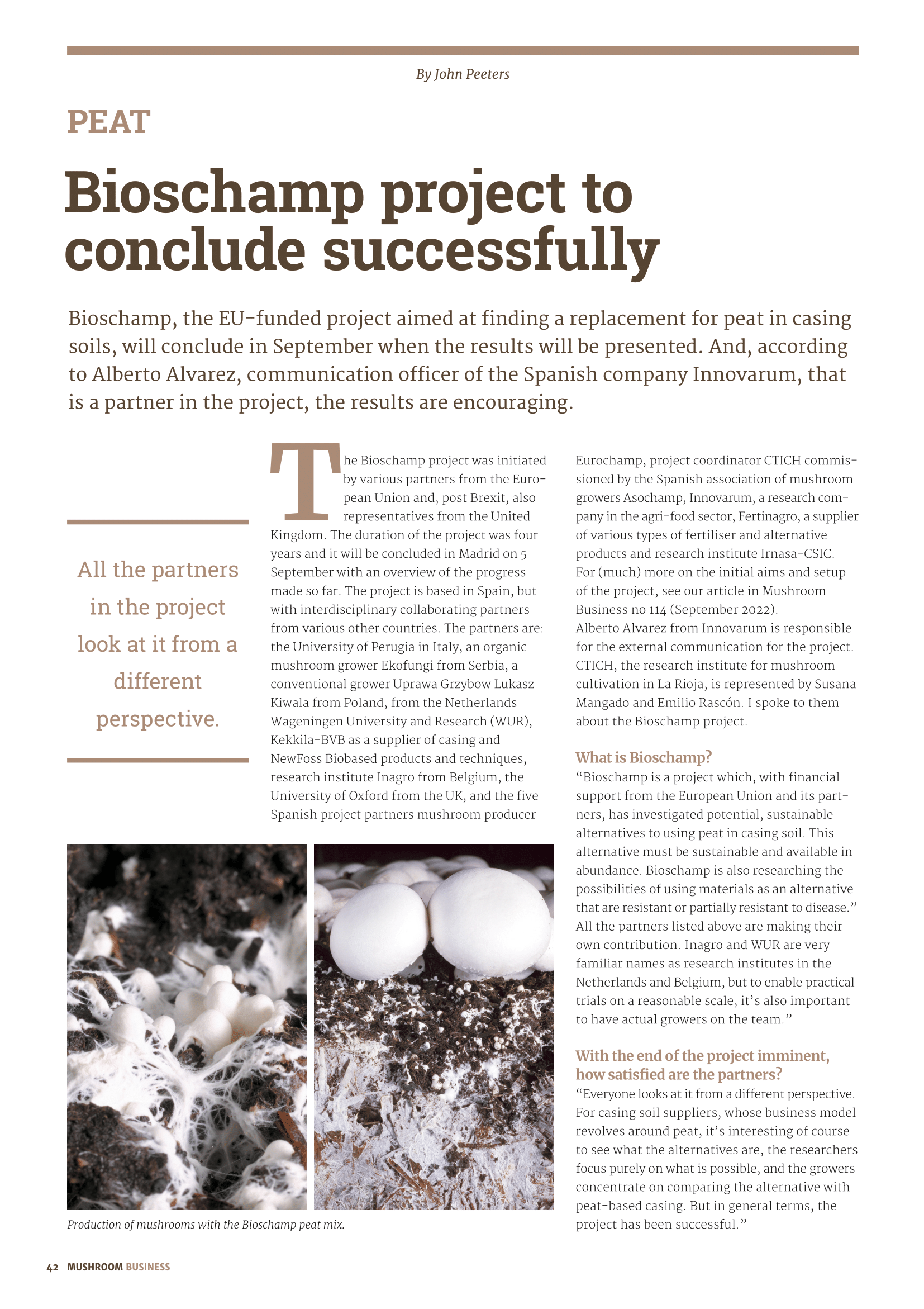

BIOSCHAMP interview with Mushroom Business

First published in Mushroom Business 125, republished with permission by the publisher. Copyright Global Roel Media BV, www.mushroombusiness.com